wholelottasupplies

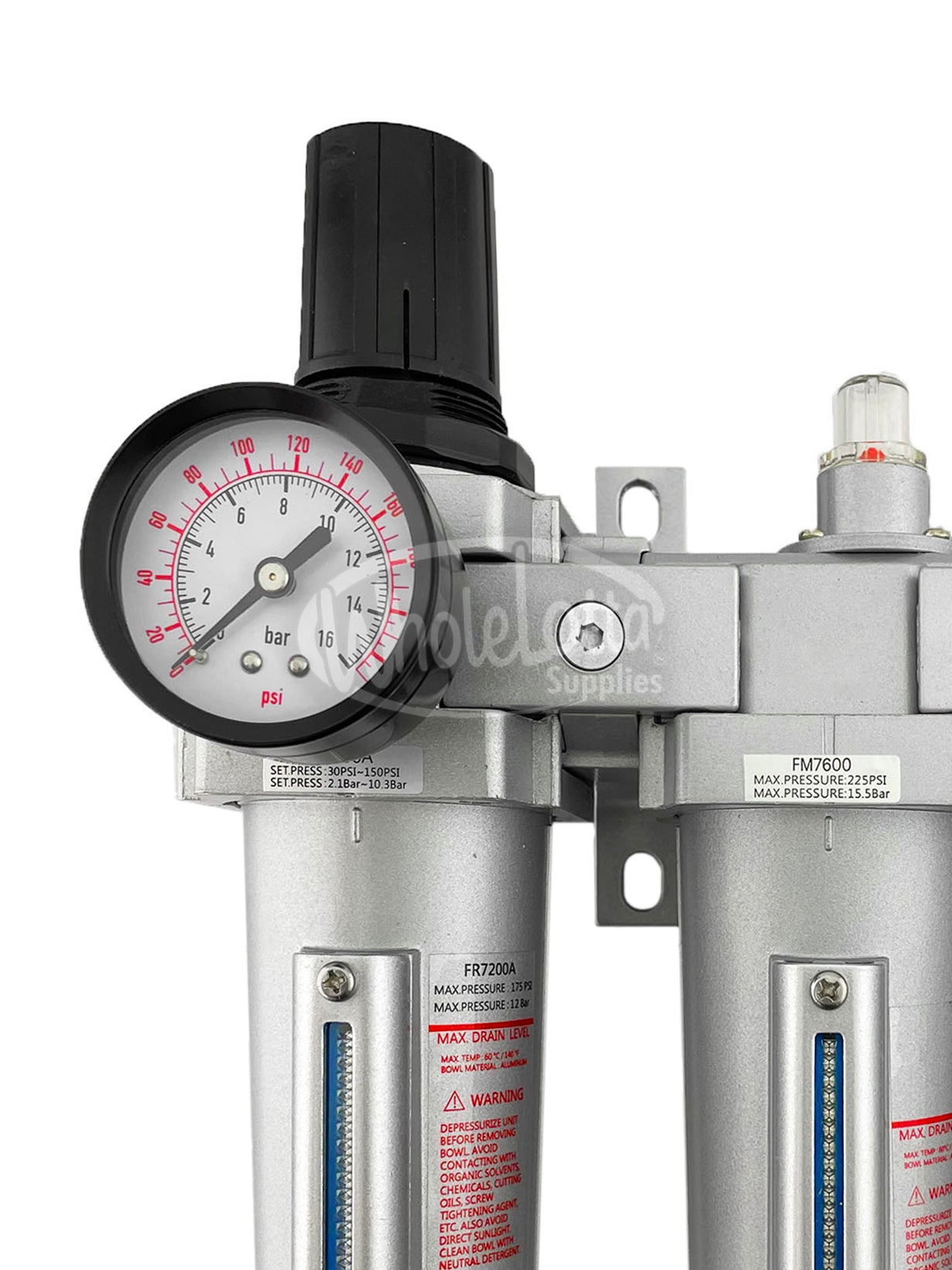

HEAVY DUTY 1/2″ NPT 3 Stage Industrial Grade Filter Regulator Coalescing Desiccant Dryer System w/ Auto Drain

HEAVY DUTY 1/2″ NPT 3 Stage Industrial Grade Filter Regulator Coalescing Desiccant Dryer System w/ Auto Drain

Regular price

$159.90 USD

Regular price

$175.00 USD

Sale price

$159.90 USD

Unit price

per

Tax included.

Shipping calculated at checkout.

Couldn't load pickup availability

1/2″ NPT HEAVY DUTY Filter Regulator Coalescing Desiccant Dryer System

Industrial Grade

With Auto Drain

FR-FLM764NA

This unit will regulator your incoming and outgoing air pressure while removing moisture water, moisture vapor and oil from your compressed air lines, then finally drying out the super clean air with an in-line desiccant air dryer

FEATURES:

- 1/2″ NPT MEASURES 0.850″ OUTSIDE THREAD DIAMETER IN INCHES.

- 175 PSI Max Input.

- STAGE 1: Water Trap Filter / Pressure Regulator. Equipped with 5 micron element to remove 95% of the initial moisture and debris from your compressed air line. Regulator adjusts pressure from 7 to 175 psi. 5oz metal bowl with visible sight glass.

- STAGE 2: Coalescing Filter Also known as oil removing filter armed with a 0.01 micron element that removes 99.98% of moisture, moisture vapor and oil that made its way past your stage 1 filter. 5oz metal bowl with visible sight glass. Red indicator pops up when time for filter change.

- STAGE 3: Desiccant Air Dryer, Dries out your super clean air before going downstream to your air tools. Uses 5oz desiccant beads in the bowl. Beads turn from blue to pink when time to change.

- INCLUDES 2 Blue Desiccant Beads Bags (3.5oz per bag)

-

Wall Mounting Bracket & Internal Float Drain (Auto Drain)

TOP QUALITY

MADE IN TAIWAN

REPLACEMENT GUIDE:

STAGE 1: Particulate Filter Replacement SKU F7007.

STAGE 2: Coalescing Filter Replacement SKU FM7607.

STAGE 3: Dessicant Beads Replacement SKU DC-01

This filter regulator with in line dryer is the most economical option for removing water, water vapor and oil from your compressed air lines, then drying the air before hitting your pneumatic tools downstream.

The absolute best way to separate water from your compressed air lines starts with the compressed air lines themselves. Always force air to climb vertically while pooling water is carried downwards by gravity. Usually into some sort of drain or ball valve that is drained out periodically. Compressed air dryers reduce the quantity of water vapor, liquid water, hydrocarbon, and hydrocarbon vapor in compressed air. Moisture in compressed air is harmful.

Water damages a compressed air system several ways. The result is lower productivity, increased maintenance, and higher operating costs. You can minimize the damage wet compressed air can inflict on your system by drying it.